Smart Industry

Monitoring

Heliotics CORE

Fully Modular and Scalable No-Code IoT Platform for Smart Monitoring of Industrial Facilities.

Smart

Industry

Monitoring

WE PROVIDE

Software solutions for Smart Industry Monitoring

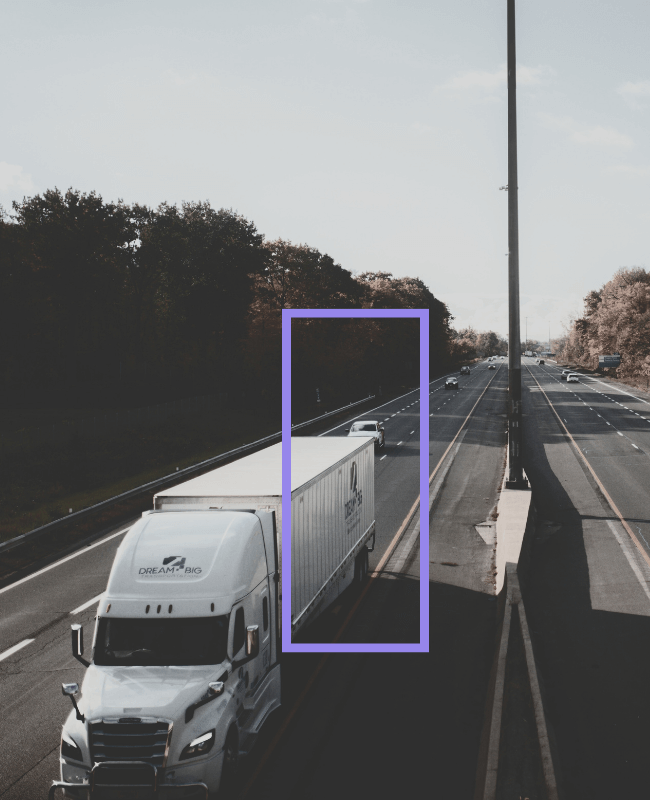

Heliotics provides complete software solutions for production and industry monitoring with the use of Internet of Things (IoT) leveraging existing LoRaWAN and NB-IoT network coverage and smart sensors integrated into a fully modular platform Heliotics CORE.

We enable manufacturers and industrial facilities to use our scalable NO-CODE platform to have full control over their production sites and processes.

WE PROVIDE

Software solutions for smart industry monitoring

WE PROVIDE

Smart industry monitoring solutions

Heliotics provides complete software solutions for production and industry monitoring with the use of Internet of Things (IoT) leveraging existing LoRaWAN and NB-IoT network coverage and smart sensors integrated into a fully modular platform Heliotics CORE.

We enable manufacturers and industrial facilities to use our scalable NO-CODE platform to have full control over their production sites and processes.

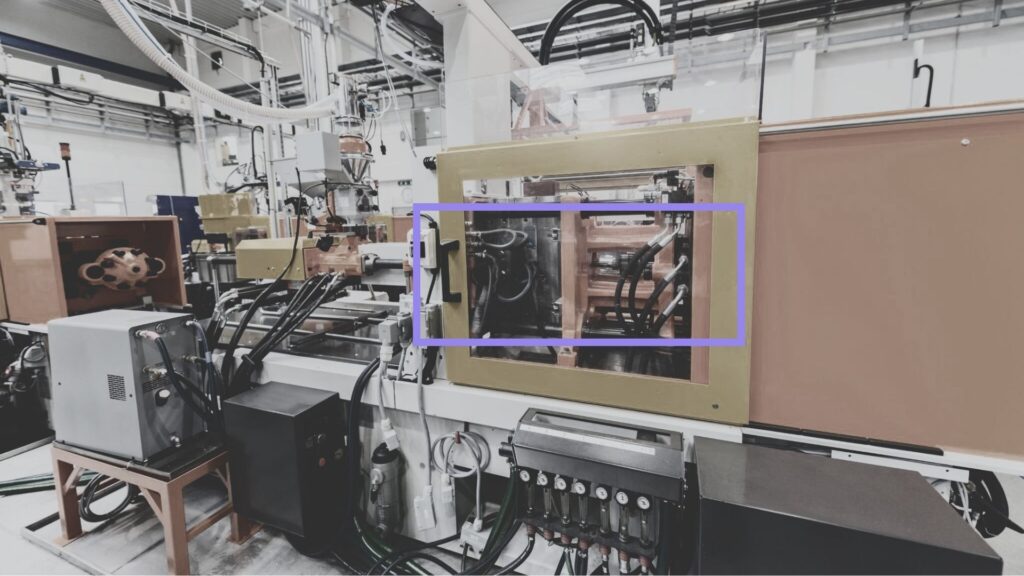

CONNECT

Any IoT sensor on any network

GET DATA

From any process, object or area

ANALYZE

Data to identify issues and inefficiencies

IMPROVE

To be efficient, cost-saving and have control

CONNECT

Any IoT sensor on any network

GET DATA

From any process, object or area

ANALYZE

Data to identify issues and inefficiencies

IMPROVE

To be efficient, cost-saving and have control

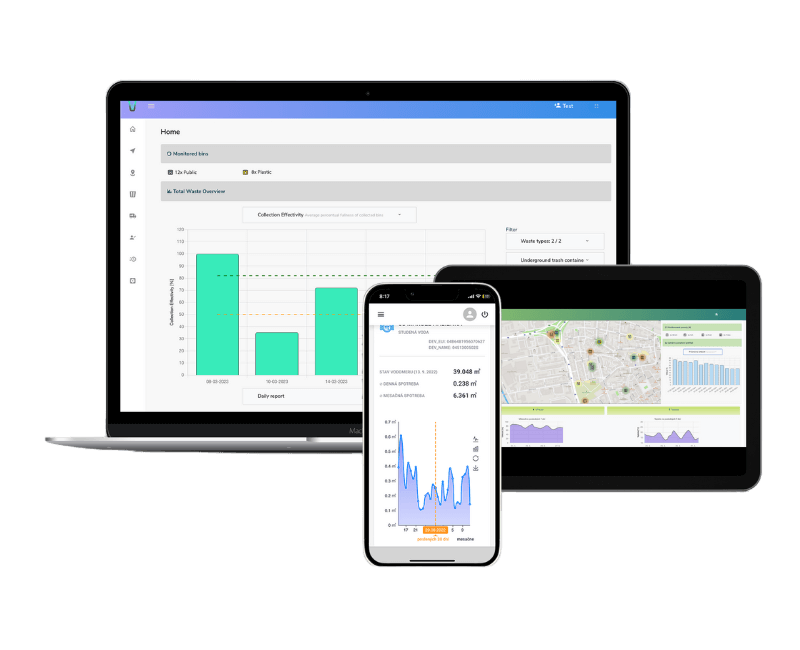

Our Platform

Heliotics CORE

Complete industrial monitoring at one place

Complete industrial monitoring at one place

There is no more need to use multiple apps for different sensors. Now all can be managed easily and at once, with no programming skills required.

Realize your Industrial IoT use cases with ready-made dashboards, data analytics and exports, and real-time alerts using Heliotics CORE for a simple and convenient industry monitoring.

and more…

There is no more need to use multiple apps for different sensors. Now all can be managed easily and at once, with no programming skills required.

Realize your Industrial IoT use cases with ready-made dashboards, data analytics and exports, and real-time alerts using Heliotics CORE for a simple and convenient industry monitoring.

and more…

Features

Dashboards and data exports

Multiple networks

Many supported devices

Real-time alerts

Customization and whitelabel

Easy onboarding

For all platforms

Integrate with API

Heliotics Industry

Ready to Monitor

Heliotics CORE

Benefits

Continuous Monitoring

Have your industrial facility under control from anywhere. On any device, 24/7. Easy, simple, and convenient.

Reliable Data

Work with the analytics and insights into your production. Access better information for improved reporting.

Reliable Data

Work with the analytics and insights into your production. Access better information for improved reporting.

Increased Productivity

Analyze processes, streamline operations, save on costs. Optimize your production to reach maximum efficiency.

Additional Packages

Heliotics Subs

Want even more insights into your production and processes?

Add en extra package on top of Heliotics CORE and work with more detailed analytics, exports and other features.

Terra

Smart soil

monitoring

Get to know

Our Services

Providing

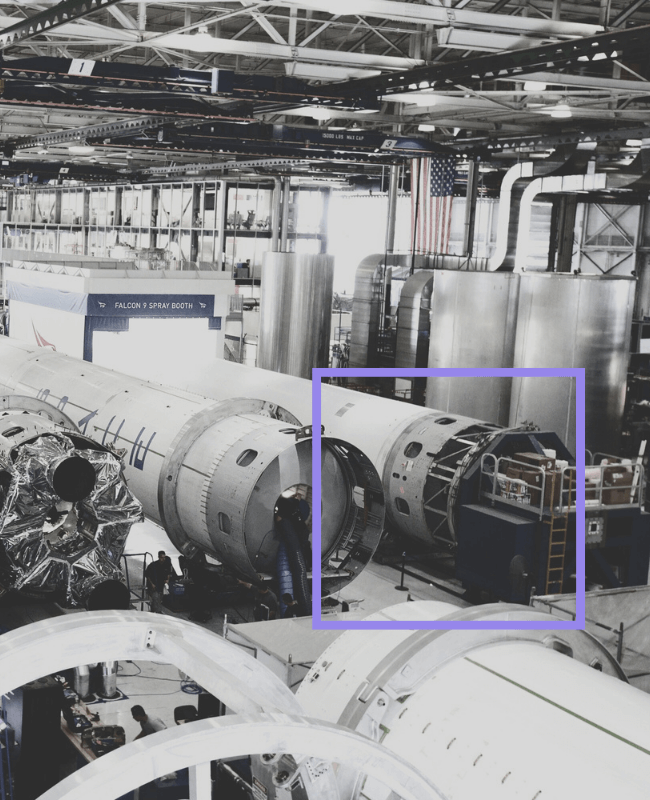

Connectivity

Internet of Things (IoT) systems and devices need a communication network that can support the transmission of data from and to the field-deployed devices and sensors.

LoRaWAN and NB-IoT networks are currently the dominant communication protocols globally for IoT deployments. We are providing everything including consultancy, gateways, installation or choosing the right protocol or antenna.

LoRaWAN

Network Server

The LoRaWAN® Network Server (LNS) plays a vital role in the framework of Long Range Wide Area Networks, guaranteeing secure and effective communication between LoRaWAN® gateways, end-devices, and applications.

To have it under control, we offer our own solution LORAWAY – the LNS designed for seamless operation and management of your LoRaWAN® infrastructure. Developed together in cooperation with our partner UPLINK.

The LoRaWAN® Network Server (LNS) plays a vital role in the framework of Long Range Wide Area Networks, guaranteeing secure and effective communication between LoRaWAN® gateways, end-devices, and applications.

To have it under control, we offer our own solution LORAWAY – the LNS designed for seamless operation and management of your LoRaWAN® infrastructure. Developed together in cooperation with our partner UPLINK.

WEB | MOBILE | APP

Software

Heliotics provides users with customized data visualization dashboards to get the best insights from smart sensors operation.

If you want to control, track, measure, evaluate or set alerts, every solution is possible to help you clearly visualize your processes and be in full control.

We provide simple deployment and integration of fully customized solutions for businesses and individuals and the security of your data is our main concern.

Development Software we use

Smart

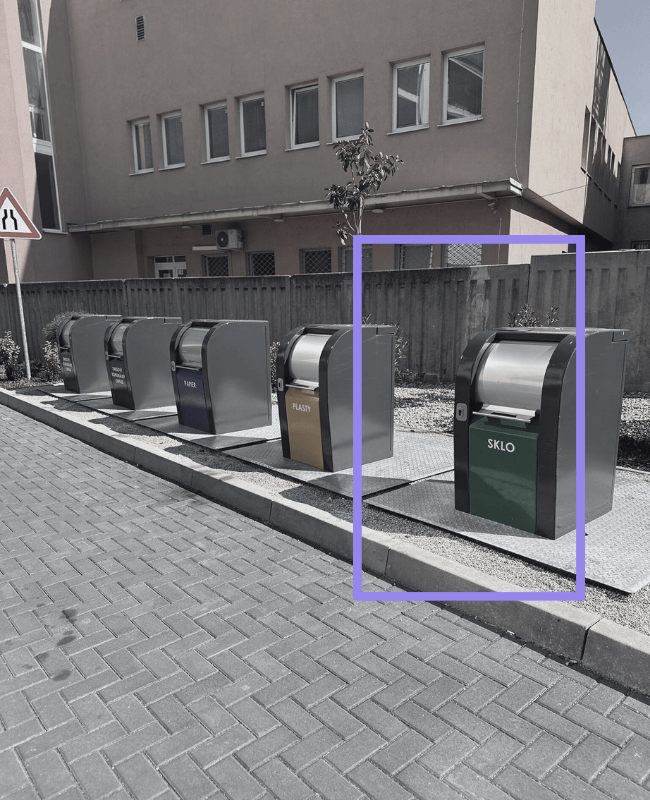

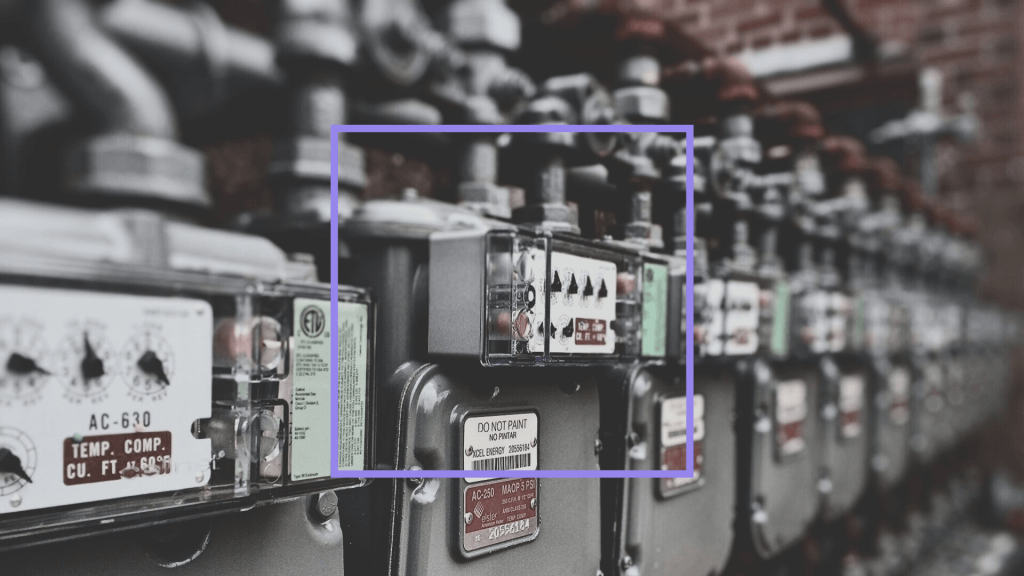

IoT Sensors

We work with certified suppliers to provide customers with smart sensors for every application.

We are helping businesses and individuals deploying IoT sensors on the LoRaWAN or NB-IoT network. Reach out and we will assist you in solving your challenges using the Internet of Things immediately.

Customization

Heliotics Lab

Sensors development

We are working only with the best hardware in the market. We partnered up with manufacturers with extensive experience in developing LoRaWAN and NB-IoT based sensors.

Software development

Whether you need to finetune existing solutions or need entirely new software, we are here to help you overcome any dashboard development needs.

Project development

If you have processes that need to be monitored, we are prepared to guide you through the potential of IoT and LPWAN to help you implement the solution you need. We like lean ideology.